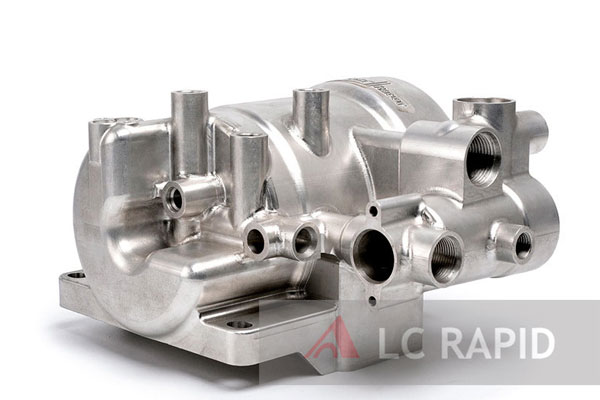

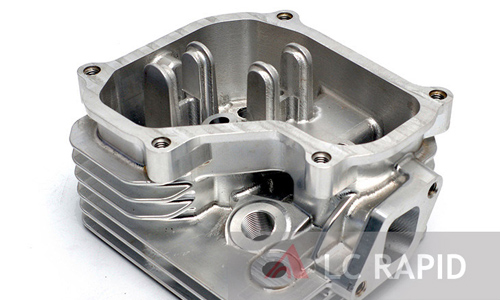

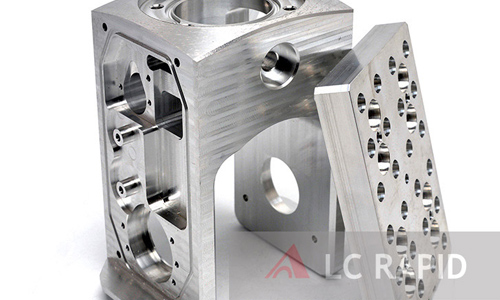

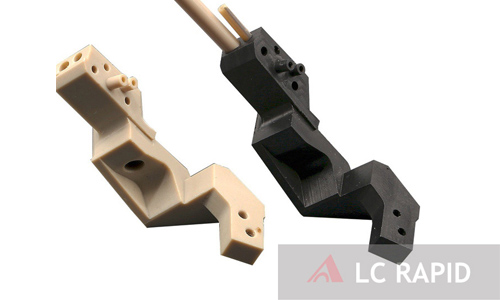

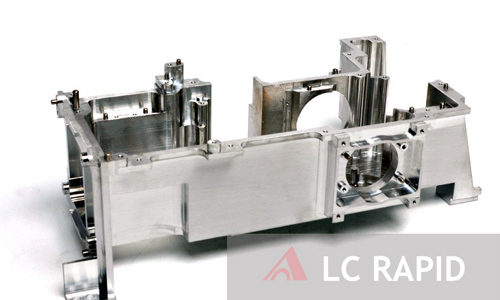

At LC Rapid, our precise, quick-turn, custom CNC machining services in China make parts from various certified metal and plastic materials. Our CNC services include milling, turning, wire EDM, and much more.

With advanced CNC machining centers and experienced employees, we offer the same high-quality parts and satisfactory services to large and small companies alike, from Fortune 500s to innovative start-ups.

Introduction of CNC Machining Services

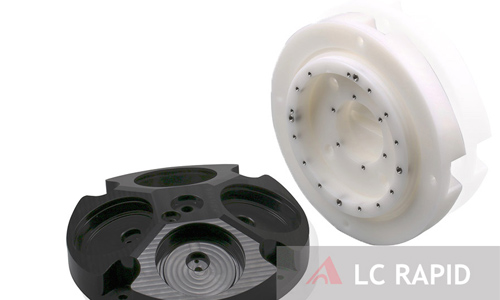

CNC (Computer Numerical Controlled) is an automated manufacturing process to remove materials from a simple plastic or metal block with a serial of cutting tools to make the custom CNC machined parts. Advanced software is used to control the high precision machining according to the required specification of the CAD (Computer Aided Design) model provided by the customer. The support from LC team of engineers will program the CNC machining center to create the final products with a high level of part complexity, and provide exceptional surface finishes. As a professional CNC machining solutions inc, we are continuously offering a cost-effective CNC custom machining whether you need prototypes, production orders or mold tools that are used for plastic injection molding or pressure die casting services.

Advantages of Precision CNC Machining

Fast Turnaround

Fast Turnaround

Using the highly advanced CNC machines, LC Rapid can manufacture precise parts in 1 day.

Precision

Precision

High dimensional tolerances and precision can be assured by applying CNC machining.

Different Finishing Options

Different Finishing Options

CNC machining offers great surface finishing, we also offer a full range of finishes on metal and plastic parts, from sand blasting, anodizing to plating, brushing, polishing to painting.

High Scalability

High Scalability

CNC Machining is suitable from one single part to production runs 100,000 parts thanks to robust, round-the-clock machines.

Material Selection

Material Selection

There are a wide range of certified rapid prototyping and production materials can be selected, from commonly used aluminum, stainless steel and plastics to more exotic materials like titanium, carbon fiber .

Cost Effectiveness

Cost Effectiveness

Low investment in tooling and quick removal of raw materials guarantee CNC machining a cost effective way for both prototyping and high production volumes.