+86-18898486814

sales@lcrapid.com

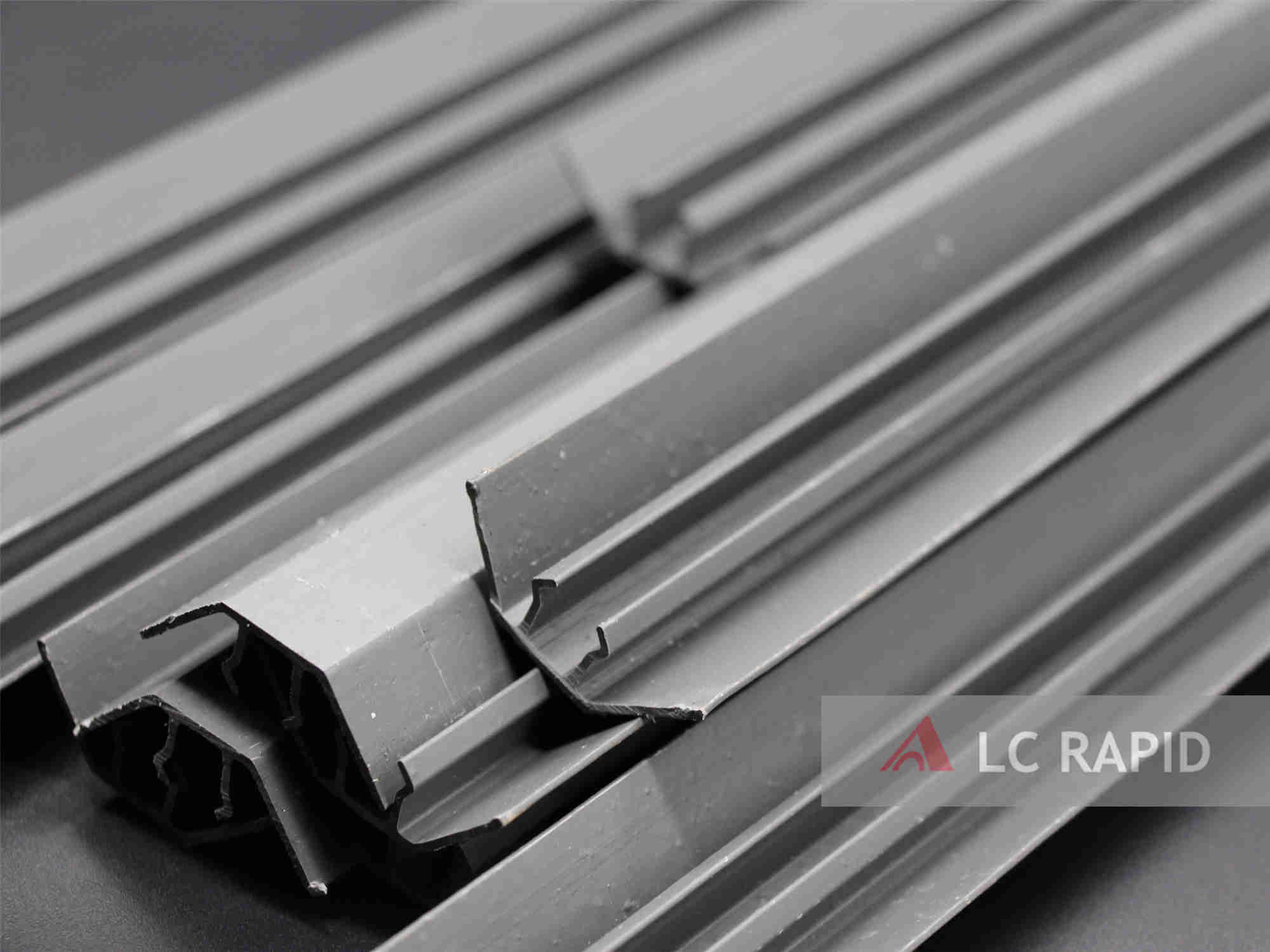

Industrial aluminum profile has a wide range of applications and strong versatility. It is famous for its environmental protection, convenient assembly and disassembly, time saving and long service life. Industrial aluminum profiles have many varieties and specifications, suitable for various types of mechanical devices; no welding, convenient size adjustment, easy structure modification; strict dimensional tolerances, high surface finish requirements; convenient and quick assembly work, high productivity; the surface is anodized, which has characteristics of anti-corrosion, spray-free, beautiful appearance, increasing the added value of the product. Thus, this material is very suitable for sheet metal fabrication.

1. Cutting

The most suitable methods for cutting aluminum profiles are as follows:

(1) Shearing machine: Use the shearing machine to cut out the shape of the unfolded drawing. If the length and width dimensions have punching and corner cutting, then turn the punching machine and die punching and corner cutting to form;

(2) Punch: The punch is used to punch the unfolded flat parts on the plate in one or more steps on the sheet into various shapes. Its advantages are short working hours, high efficiency, high precision, low cost, suitable for mass production;

(3) Sawing machine: low cost and low precision;

(4) Plasma cutting: mainly for aluminum cutting effect.

(5) Laser cutting: using laser cutting method to cut out the structure and shape of the flat sheet on a large flat sheet, it is necessary to write a program, and it can cut a variety of complex shapes of flat parts, with high cost and accuracy greater than 0.1mm;

2. Flanging

It is also called drawing holes, which is to draw a slightly larger hole on a smaller base hole, and then tap it. It is mainly used for thin sheet thickness and normal shallow flanging around the hole. The thickness will basically not change. Then you can tap directly.

3. Punch

Utilize the processing procedures of mold forming, generally punching, cutting corners, blanking, punching convex hull, punching and tearing, drawing holes, forming and other processing methods, its processing requires corresponding molds to complete the operation, such as punching blanking mold, convex mold, tearing mold, hole punching mold, and forming mold.

4. Pressure riveting

Pressure riveting mainly includes pressure riveting nuts, and screws. The operation is completed by hydraulic pressure riveting machine or punching machine, riveting them to the sheet metal parts, and the expansion riveting method, which needs to pay attention to the directionality.

5. Bending

It is the part that folds the flat aluminum profile into the required radian or camber. The processing needs to be completed with a folding bed and corresponding bending molds, and it also has a certain bending sequence. The principle is that the first bending that does not interfere with the next cut will cause interference after the bending.

6. Welding

Welding is a manufacturing process and aluminium extrusion technology for joining aluminum profiles by heating, high temperature or high pressure.

The display cabinet made of sheet metal fabrication services of aluminum profile is the main carrier of commercial products and the main frame of commercial space. It needs to have practical, artistic, economic, safety and humanized functional requirements. Different products have different display cabinet forms and functions. The quality of the design and manufacture of shopping mall display cabinets will directly affect the sales of goods and the brand image of the company.

Display cabinets made of sheet metal fabrication of aluminum profiles are widely used in company showrooms, exhibitions, department stores, advertising, etc., in industries such as handicrafts, gifts, jewelry, mobile phones, glasses, watches, tobacco, alcohol, and cosmetics. For example, Wal-Mart large supermarkets often use such display cabinets to display products, which is more attractive to customers.