Magnesium is excellent with it’s extraordinary strength-to-weight ratios and outstanding mechanical performance.

The commonly-used magnesium alloy material is AZ91D.

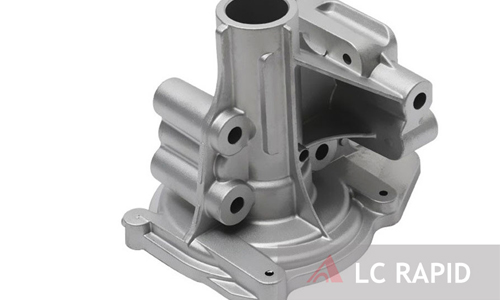

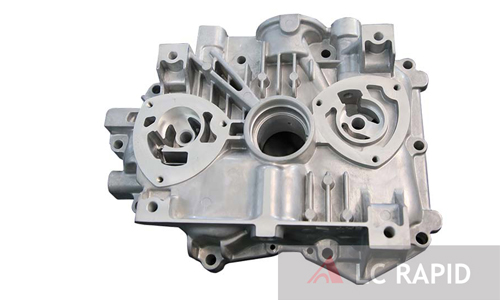

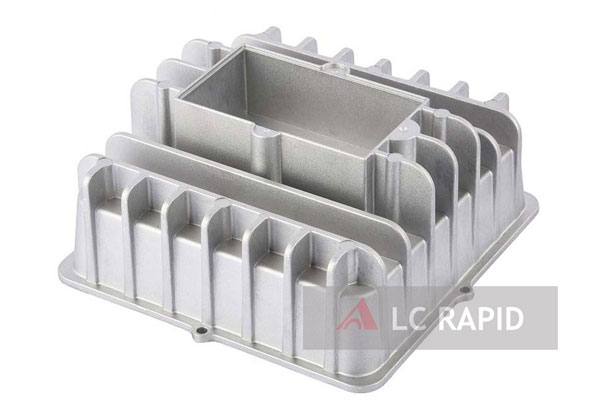

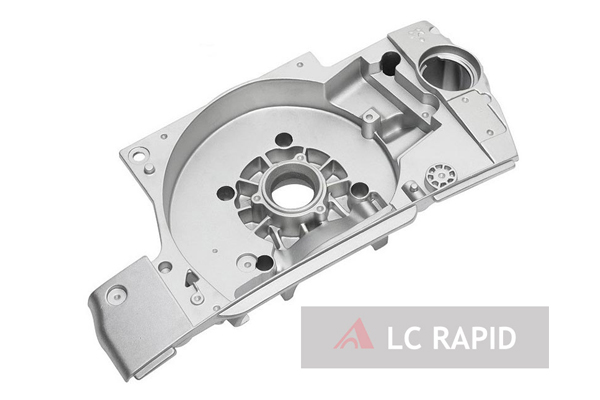

Pressure die casting is the optimal choice for producing medium to high volumes of metal parts in aluminum, magnesium and zinc alloy. LC Rapid offers a full line of pressure die casting China services, including mold tool making, die casting, machining, different surface post finishing options. As one of the leading pressure die casting manufacturers in China, we invite you to experience our excellent services at an economical price and with reliable quality when you send us your 3D models for a free quote.

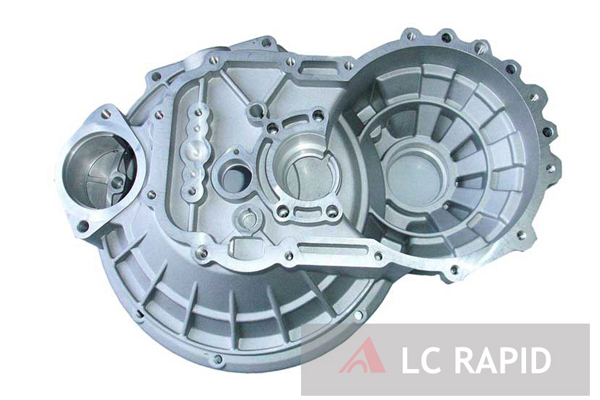

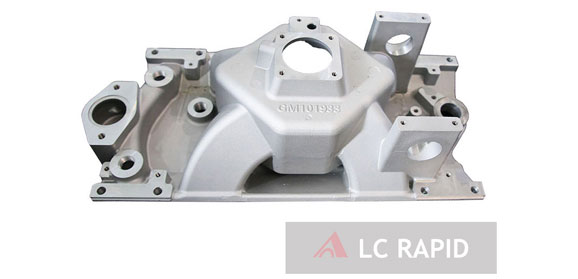

Pressure die casting is a quick and one of the most cost-effective manufacturing methods to produce dimensional accurate metal parts. Basically, types of pressure die casting process is made by injecting molten metal into a reusable steel molds(also called dies or tools)under high pressure.

Durability

Durability

High Pressure Die Casting process produces highly durable parts well-suited for both functional prototypes and end-use production.

Smooth Surface

Smooth Surface

The high pressure casting process provides smoother finishes than all other forms of casting.

There are following steps after we receive the order from you:

Review drawing and assess any potential manufacturability issues and defects in DFM analysis stage.

Verify the tool material.

Use our full in-house machine shop to fabricate the mold tool.

Apply lubricant to ease the removal of the cast part and maintain the mold temperature.

Perform in process control during the casting process to ensure quality.

Offer a broad range of finishing services to make you parts flawless.

Inspect finished parts to exceed your expectations.

The tolerances standard we are using is from NADCA, which is showing in below table (linear dimensions). For other tolerances please refer to NADCA. However, if you need a tighter tolerance, then a tighter tolerances standard can be achieved once we have confirmed your pressure die casting design.

Magnesium is excellent with it’s extraordinary strength-to-weight ratios and outstanding mechanical performance.

The commonly-used magnesium alloy material is AZ91D.

High pressure die casting mold tool material is only referred to cavity/ inside of tooling, normally the mold base or other components are 45# or a cheaper material.

Normally we will use H13 as the cavity material. If the parts require large quantity in the future, we can consider to use imported material, such as 8408, 8407 from Sweden, but they are much more expensive.

We specialize in superior aluminum, magnesium and zinc alloy die casting. When finding out what material you are going to use for the project, you need take many factors into consideration, including cost, weight, performance, cast ability, weather condition and application environment.

Aluminum is known for its great temperature resistance and extremely lightweight. Besides, it is the most suitable choice for the exterior parts because it can be highly polished.

Common high pressure die casting aluminum alloys are ADC12, A380, and A413.

ADC12: (Japanese designation) the most common aluminum alloy, which is used a lot for parts with no special requirements.

A380: (American designation) the most common aluminum alloy used in the USA.

A413: better but more expensive.

Zinc is ideal for applications that require high strength and strong corrosion resistance. Zinc alloys are an great choice for plating. It is also highly desirable for die casting parts because it is the cheapest one.

Zamak and Mazak are the same meaning as Zinc alloy. The common material is Zinc 3# and Zinc 5#.

We would suggest this finish if your design is an visual part and has high quality requirements. Painting is commonly-used for indoor products.

It is generally used to protect products from oxidation.

The surface will not be the same beautiful as CNC parts after sand blasting process.

Impregnation is ideal for the parts require sealing function, such as automobile products or signal related products. The cost will be quite expensive if the product has many threads. The reason is that it will take time and cost to rework the threads after impregnation.

Powder coating is an excellent choice for the parts require high corrosion resistance. The powder coating appearance cannot be as great as painting. Normally, it is generally used for the parts without high visual requirements. Color is limited to black, white and grey etc.

We recommend using hard anodizing to improve wear resistance.

We are able to provide you with die casting solutions for all types of aerospace applications.

Pressure die casting is a great choice for electronic cabinets and enclosures in the electronics industry.

No matter you need fibre optic transceivers or satellite communications, we are here to offer the solution.

LC Rapid builds custom enclosures, well-suited for either lightweight while remaining pressure die casting applications or when a great degree of good thermal swing resistance and corrosion resistance is needed.

Aluminum die cast housings are light weight and durable, making them suitable for a varieties of motor housings such as portable air pump motor housing, water pump motor casing, fan motor casing.

Pressure die casting is an great choice to produce high volume of hydraulic cylinder, the pressure casting process will give uniformity of metallurgical structures with low segregation.

Just send us the parts’ 2D and 3D drawings, we can provide Design For Manufacture (DFM) service and quotation for you.

Typically, LC Rapid offers 3-5 pieces of first articles for evaluation.

You can specify your color by telling us your desired RAL or Pantone color codes. If you don’t have the color code, you can send us a color chip or a physical sample for us to match your specification.